Wire drawing is a manufacturing process used to create wire by reducing the diameter of a metal rod through a series of dies. Here’s a step-by-step overview of the process:

- Material Selection: Start with a metal rod, usually made of copper, aluminum, or steel, which has a larger diameter than the desired wire.

- Preparation: The rod is cleaned and may be annealed (heat-treated) to make it more ductile, allowing for easier drawing.

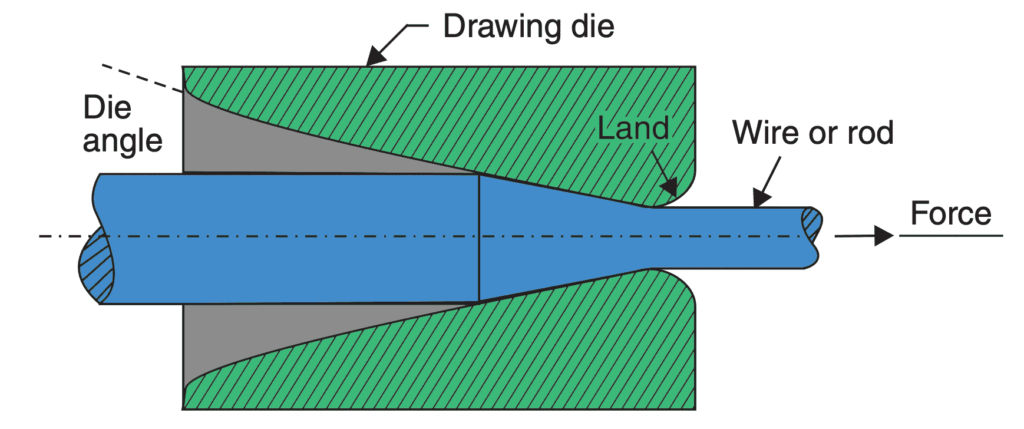

- Drawing Dies: The rod is fed through a series of drawing dies. Each die has a specific opening size, gradually decreasing in diameter.

- Drawing Process:

- The rod is pulled through the first die, reducing its diameter and elongating it.

- This is typically done using a wire drawing machine, which applies tension to pull the rod through the die.

- Lubricants are often used to reduce friction and heat during the drawing process.

- Reduction Stages: The process may involve multiple stages, with the wire being drawn through several dies to achieve the desired final diameter. Each pass may involve a smaller reduction in diameter.

- Annealing: After several passes, the wire may become too hard and brittle. It is then annealed to restore ductility.

- Coiling: Once the wire reaches the desired thickness, it is coiled for storage or further processing.

- Finishing: Additional treatments, such as surface coating or polishing, can be applied to improve the wire's properties or appearance.

- Quality Control: Finally, the wire is inspected for diameter consistency, surface quality, and mechanical properties.

This process allows for precise control over the wire’s dimensions and properties, making it suitable for various applications, from electrical wiring to structural components.